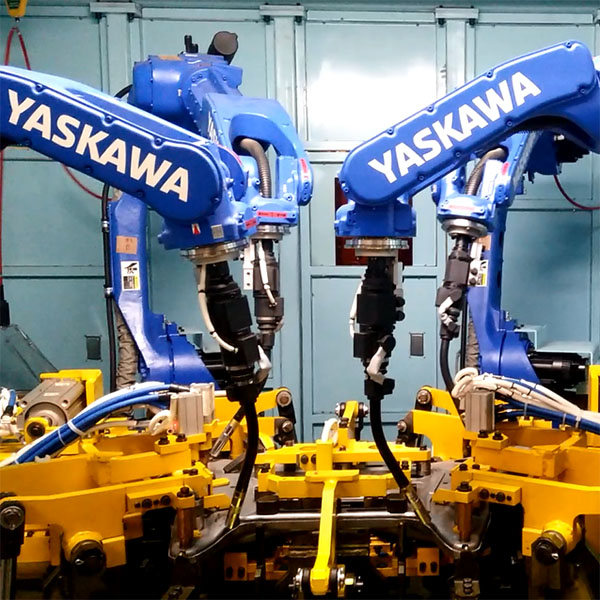

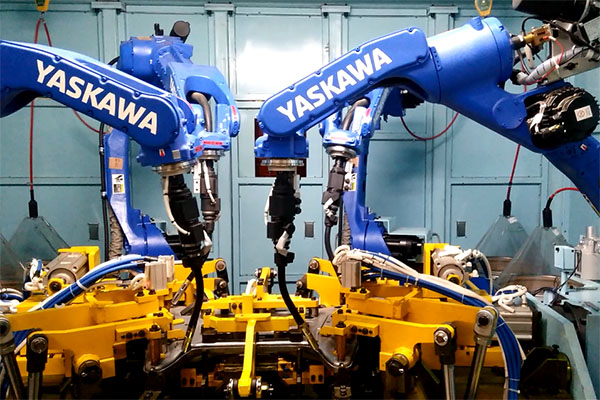

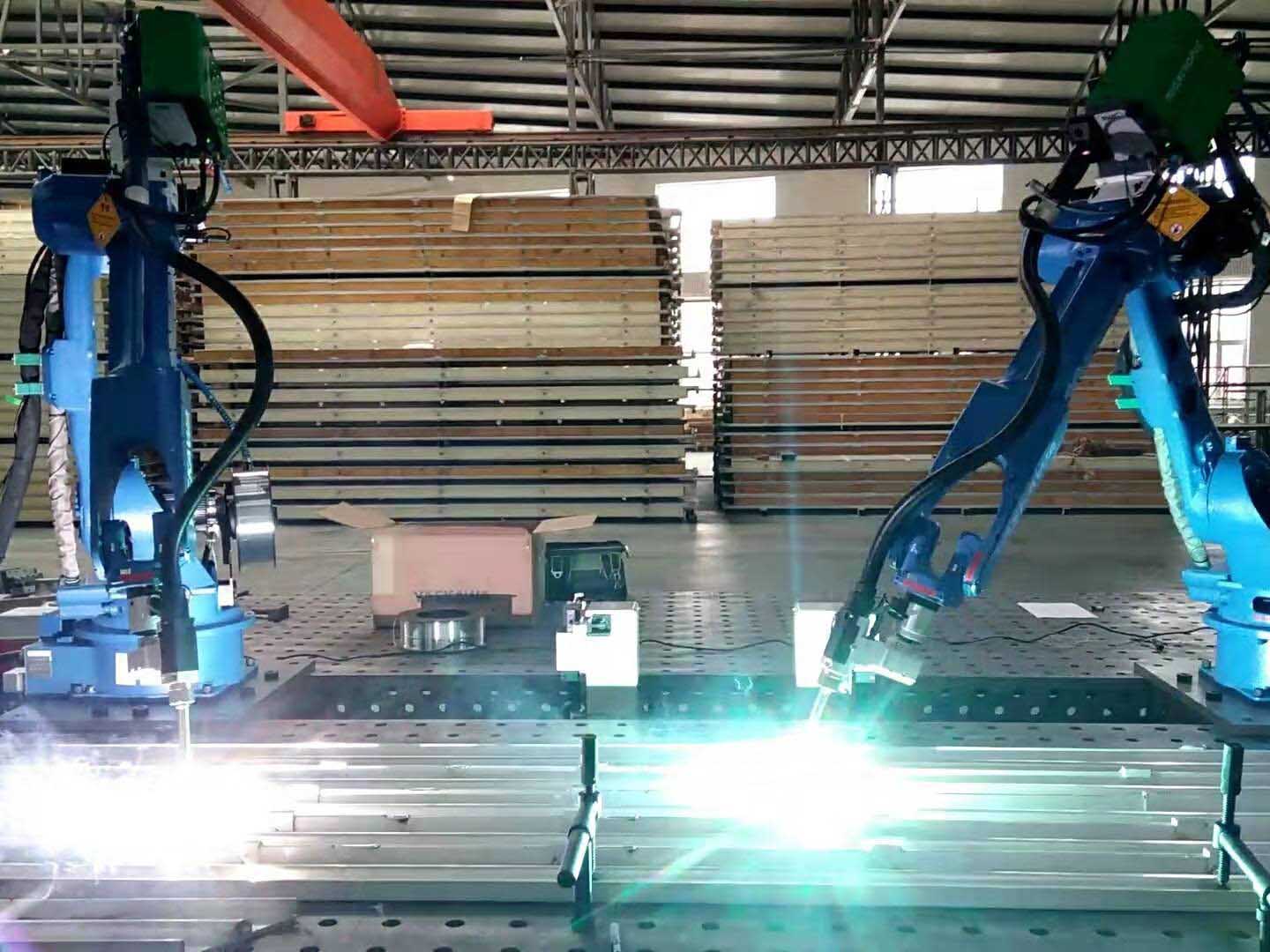

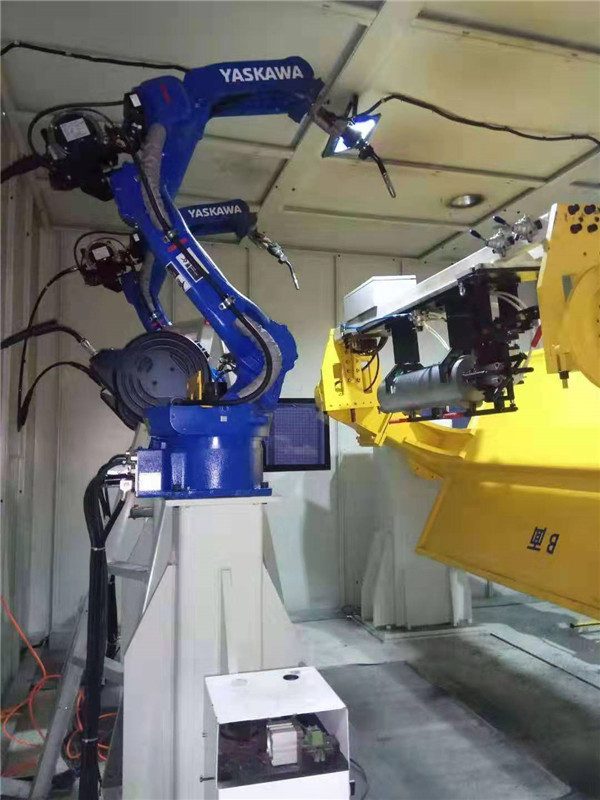

Welding irobhothi workcell / welding irobhothi work station

Welding irobhothi workcellingasetshenziswa ekukhiqizeni, ekufakeni, ekuhloleni, kwezokuthutha nakwezinye izixhumanisi zokukhiqiza, futhi asetshenziswa kabanzi ezimotweni zezimoto nezingxenye zezimoto, imishini yokwakha, izinto zokuhamba ujantshi, izinto zikagesi ezine-voltage ephansi, ugesi, imishini ye-IC, imboni yezempi, ugwayi, ezezimali, imithi, i-Metallurgy, izimboni zokunyathelisa nezokushicilela zinezinhlobonhlobo zezinhlelo zokusebenza. Ayisizi nje kuphela ukugadwa kwenkampani, yonga izindleko, kodwa futhi iqinisekisa ikhwalithi yokushisela, ukusebenza kahle okuzinzile, nokusebenza okuphezulu kokuphepha. Kuwukukhetha kohlu olubanzi lwabasebenzisi.

Njengengxenye yezobuchwepheshe yenqubo yokushisela, i-weldingindawo yokusebenza yerobhothiiba "isiteshi" esinomsebenzi wokushisela kulayini wokukhiqiza. Iwuhlelo lokulawula oluzimele, yonke imisebenzi noma izenzo zerobhothi ziqedwa ngohlelo lokulawula lwerobhothi lokushisela ngokwalo.

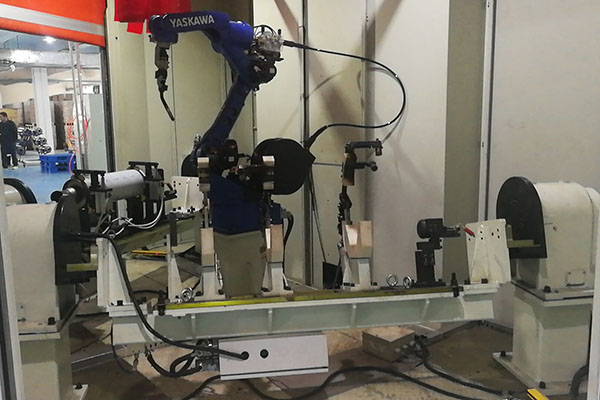

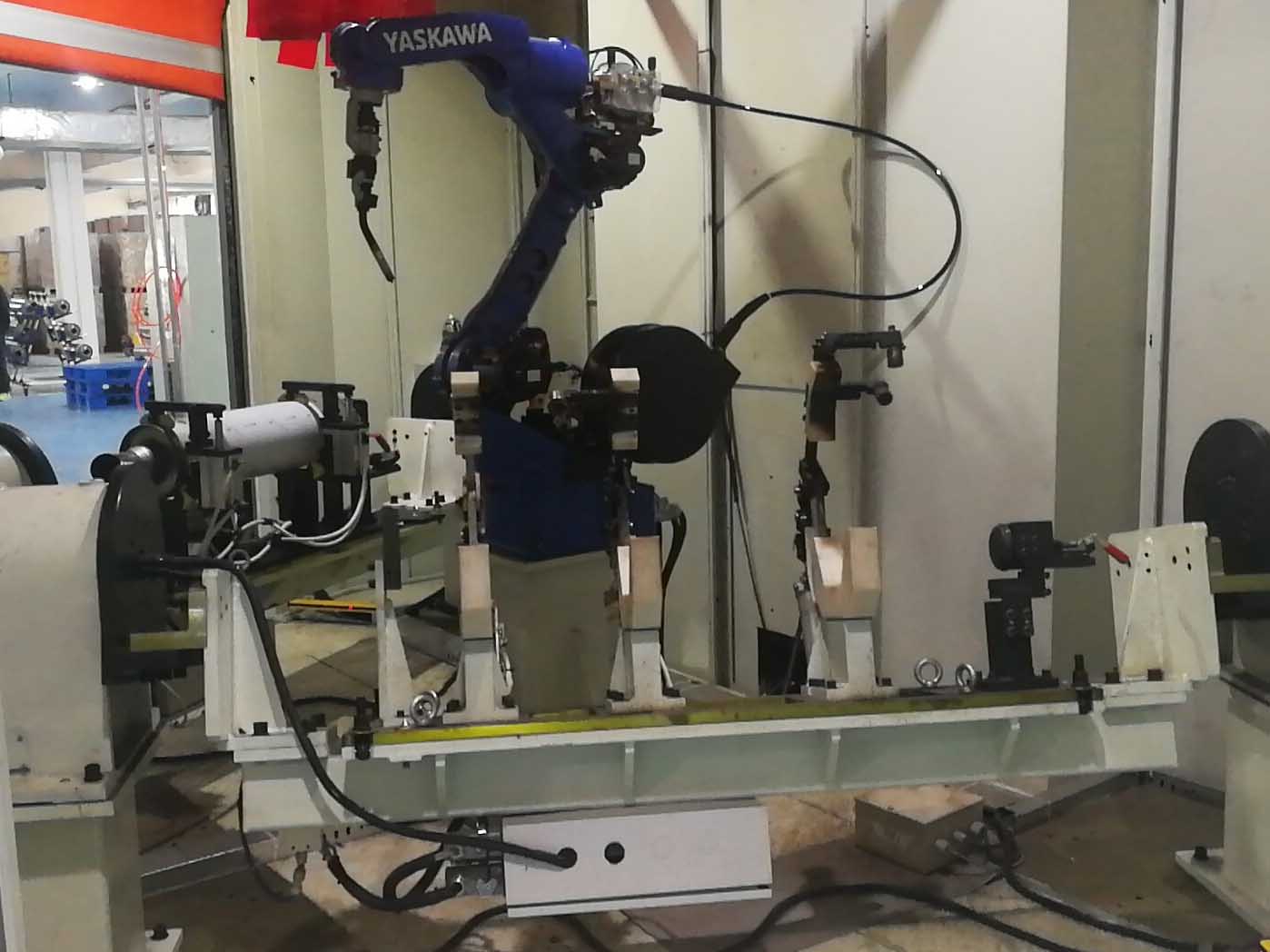

Ngaphezu kwamarobhothi wokushisela,welding irobhothi workcellfuthi zinama-ground rails, ama-positioners, amatafula aphendukayo, amasistimu okulandelela i-weld, uthango lokuphepha, izinto zokuhlanza izibhamu, amasistimu okuphepha, kanye nemishini yangaphandle esebenza namarobhothi okushisela.

Lapho i-welding irobhothi workstationiyasebenza, iKhabhinethi yokulawula irobhothi ithola izimpawu zangaphandle, njengokushisela, i-pendant yokufundisa, iKhabhinethi yokulawula yangaphandle, njll., futhi idlulisela idatha kurobhothi, ukuze i-welder ifinyelele indawo yokushisela futhi iqedele umsebenzi wokushisela. Isibhamu sokushisela sisebenzisa amandla aphezulu omshini wokushisela futhi ukushisa okukhiqizwa yi-voltage ephezulu kugxilwe ku-terminal ye-welding gun ukuze kuncibilike intambo yokushisela futhi iyenze ingene ezingxenyeni ezizoshiselwa. Ngemuva kokupholisa, izinto ezishiselwe zixhunywe ngokuqinile emzimbeni owodwa. I-feeder yocingo ingathumela ngokuqhubekayo futhi ngokuzinzile intambo yokushisela ngokuvumelana nemingcele emisiwe, ukuze i-welding iqhutshwe ngokuqhubekayo kanye nokusebenza kahle kwe-welding kuyathuthukiswa. Ifaniswe nesiteshi sokuhlanza izibhamu ukuhlanza i-slag yokushisela, ukufafaza uketshezi lwe-anti-spatter nokunquma ucingo lokushisela ukuze kuqinisekiswe umphumela wokushisela wekhwalithi ephezulu.

Ikhabhinethi yokulawula yangaphandle yerobhothi elishiselayo ilawula isihleli, futhi idlulisa amapharamitha ezimoto kanye nedatha kukhabhinethi yokulawula. I-motor ishayela i-weldment ukuyeka ukujikeleza, ukuze i-weldment ifinyelele endaweni efanele ye-welding futhi isize ukuqedwa kokushisela.