-

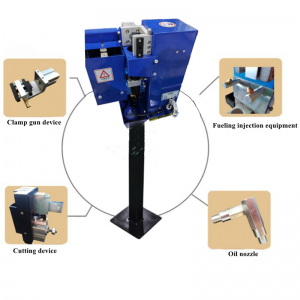

Isiteshi Sokuhlanza Isibani Sokushisela

Idivayisi yokuhlanza yethoshi yokushisela

Ibhrendi I-JSR Igama isiteshi sokuhlanza ithoshi lokushisela Imodeli yedivayisi JS-2000s Ivolumu yomoya edingekayo cishe 10L ngomzuzwana Ukulawula uhlelo I-pneumatic Umthombo womoya ocindezelwe Umoya owomile ongenawo uwoyela 6bar Isisindo cishe 26kg (ngaphandle kwesisekelo) 1. Idizayini yokuhlanza isibhamu kanye nokufutha endaweni efanayo yokuhlanza isibhamu kanye nendlela yokusika,irobhothi lidinga-asignal kuphela ukuqedela ukuhlanza isibhamu kanye nezenzo zokujova uphethiloli. 2. Sicela uqinisekise ukuthi izingxenye ezibalulekile zemishini yokusika isibhamu ivikelwe yi-ai-casing yekhwalithi ephezulu ukugwema umthelela wokungqubuzana, ukuchaphaza nothuli. 1. Sula isibhamu Ingakwazi ukususa ngempumelelo i-welding spatter enamathiselwe ku-nozzle ye-robot welding ehlukahlukene. Ngokunamathisela okuqinile "kwe-splash", ukuhlanza nakho kunemiphumela emihle. Isikhundla sombhobho we-welding ngesikhathi senqubo yomsebenzi sinikezwa ibhulokhi efana ne-V ukuze ibekwe ngokuqondile. 2. Futha Idivayisi ingafafaza uketshezi oluhle lwe-anti-spatter ku-nozzle ukwenza ifilimu yokuzivikela, enciphisa ngempumeleloukunamathela kwe-welding spatter futhi kwandisa isikhathi sokusebenzisa kanye nempilo yezinsiza. Indawo ehlanzekile izuza endaweni yesifutho esivaliwe kanye nedivayisi esele yokuqoqa uwoyela 3. Ukugunda Idivayisi yokusika izintambo ihlinzeka ngomsebenzi wokusika izintambo ezinembile nezisezingeni eliphezulu, isusa ibhola elincibilikisiwe eliseleukuphela kwentambo yokushisela, futhi iqinisekisa ukuthi ukushisela kunekhono elihle lokuqala le-Arc. Impilo ende yesevisi kanye nezinga eliphezulu lokuzenzakalela.

www.sh-jsr.com

Imikhiqizo Eshisayo - Imephu yesayithiI-Robot Palletizer, Irobhothi Lokupenda Okuzenzakalelayo, Irobhothi Lokushisela, Yaskawa Spot Welding Robot, I-Palletizing Robot, I-Yaskawa Painting Robot,

Thola ishidi ledatha noma isilinganiso samahhala

Bhala umlayezo wakho lapha futhi usithumelele wona