-

I-YASKAWA PAINTING ROBOT MOTOMAN-EPX1250

I-YASKAWA PAINTING ROBOT MOTOMAN-EPX1250, irobhothi elincane elifuthayo elinamajoyinti amaningi aqondile angu-6 eksisi, isisindo esiphezulu singu-5Kg, kanti ububanzi bungu-1256mm. Ifanele iKhabhinethi yokulawula ye-NX100 futhi isetshenziselwa kakhulu ukufafaza, ukuphatha kanye nokufutha ama-workpiece amancane, afana nomakhalekhukhwini, izibonisi, njll.

-

I-YASKAWA Automation Spraying Robot MPX1150

Ii-automation spraying robot MPX1150ilungele ukufafaza ama-workpieces amancane. Ingathwala isisindo esiphezulu esingu-5Kg kanye nobude obuvundlile obukhulu obungu-727mm. Ingasetshenziselwa ukuphatha nokufutha. Ifakwe i-miniaturized control cabinet DX200 enikezelwe ukufafaza, ifakwe ipendant yokufundisa ejwayelekile kanye nependant yokufundisa engaqhumi engasetshenziswa ezindaweni eziyingozi.

-

Irobhothi lokushisela i-YASKAWA MOTOMAN-AR900

I-workpiece encaneirobhothi lokushisela MOTOMAN-AR900, 6-i-eksisi eqondile yokuhlanganisa okuningiuhlobo, ukulayisha okukhokhelwayo okuphezulu okungu-7Kg, ukuphakama okuvundlile okuphezulu okungu-927mm, kulungele iKhabhinethi yokulawula ye-YRC1000, ukusetshenziswa kuhlanganisa ukushisela kwe-arc, ukucutshungulwa kwe-laser, nokubamba. Inokuqina okuphezulu futhi ifanele abaningi Lolu hlobo lwendawo yokusebenza, olungabizi kakhulu, luyisinqumo sokuqala sezinkampani eziningi.MOTOMAN Yaskawa irobhothi.

-

Isiteshi Sokuhlanza Isibani Sokushisela

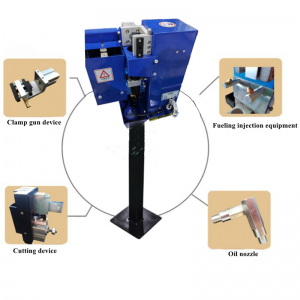

Idivayisi yokuhlanza yethoshi yokushisela

Ibhrendi I-JSR Igama isiteshi sokuhlanza ithoshi lokushisela Imodeli yedivayisi JS-2000s Ivolumu yomoya edingekayo cishe 10L ngomzuzwana Ukulawula uhlelo I-pneumatic Umthombo womoya ocindezelwe Umoya owomile ongenawo uwoyela 6bar Isisindo cishe 26kg (ngaphandle kwesisekelo) 1. Idizayini yokuhlanza isibhamu kanye nokufutha endaweni efanayo yokuhlanza isibhamu kanye nendlela yokusika,irobhothi lidinga-asignal kuphela ukuqedela ukuhlanza isibhamu kanye nezenzo zokujova uphethiloli. 2. Sicela uqinisekise ukuthi izingxenye ezibalulekile zemishini yokusika isibhamu ivikelwe yi-ai-casing yekhwalithi ephezulu ukugwema umthelela wokungqubuzana, ukuchaphaza nothuli. 1. Sula isibhamu Ingakwazi ukususa ngempumelelo i-welding spatter enamathiselwe ku-nozzle ye-robot welding ehlukahlukene. Ngokunamathisela okuqinile "kwe-splash", ukuhlanza nakho kunemiphumela emihle. Isikhundla sombhobho we-welding ngesikhathi senqubo yomsebenzi sinikezwa ibhulokhi efana ne-V ukuze ibekwe ngokuqondile. 2. Futha Idivayisi ingafafaza uketshezi oluhle lwe-anti-spatter ku-nozzle ukwenza ifilimu yokuzivikela, enciphisa ngempumeleloukunamathela kwe-welding spatter futhi kwandisa isikhathi sokusebenzisa kanye nempilo yezinsiza. Indawo ehlanzekile izuza endaweni yesifutho esivaliwe kanye nedivayisi esele yokuqoqa uwoyela 3. Ukugunda Idivayisi yokusika izintambo ihlinzeka ngomsebenzi wokusika izintambo ezinembile nezisezingeni eliphezulu, isusa ibhola elincibilikisiwe eliseleukuphela kwentambo yokushisela, futhi iqinisekisa ukuthi ukushisela kunekhono elihle lokuqala le-Arc. Impilo ende yesevisi kanye nezinga eliphezulu lokuzenzakalela. -

Yaskawa irobhothi laser welding uhlelo 1/1.5/2/3 KW lasers

I-LASER WElding

Isakhiwo seRobot Laser Welding System

1. Ingxenye ye-laser (umthombo we-laser, ikhanda le-laser, i-chiller, ikhanda lokushisela, ingxenye yokuphakela ucingo)

2. Ingalo yerobhothi yaseYaskawa

3. Izinsizakusebenza nezindawo zokusebenza (ibhentshi elilodwa/eliphindwe kabili/iziteshi ezintathu, okokumisa indawo, okokulungisa, njll.)Umshini wokushisela we-laser we-automation / 6 I-Axis Robotic Laser Welding system / I-Laser Processing Robot Integrated System Solution

Ukusuka ezimotweni kuya ku-aerospace - i-laser welding ifanele izindawo eziningi zokufaka isicelo. Izinzuzo eziwujuqu zenqubo yijubane eliphezulu lokushisela kanye nokufakwa kokushisa okuphansi.

-

YASKAWA Welder RD500S

I-Yaskawa irobhothi weld RD500S MOTOWELD umshini, Ngokuhlanganisa umthombo wamandla wokushisela olawulwa ngedijithali kanye ne-MOTOMAN, ukulawulwa kokushisela okufaneleka kakhulu ezindleleni zokushisela kuyafinyelelwa, kuhlinzeka ngekhwalithi ephezulu kakhulu yokushisela.

-

YASKAWA RD350S

I-welding yekhwalithi ephezulu ingafinyelelwa kokubili amapuleti amancane naphakathi nendawo

-

I-TIG Welding Machine 400TX4

1.Ukushintsha imodi yokushisela ye-TIG ngo-4, ukulungisa ukulandelana kwesikhathi ngo-5.

2.Isikhathi sokugeleza kwegesi ngaphambi kwesikhathi nesikhathi sokugeleza kwangemuva, amanani amanje, imvamisa yokushaya kwenhliziyo, umjikelezo wokusebenza kanye nesikhathi se-slop kungalungiswa lapho kukhethwa i-Crater On.

3.Ibanga lokulungiswa kwe-pulse frequency yi-0.1-500Hz.

-

YASKAWA Automatic welding irobhothi AR1440

Irobhothi elizenzakalelayo lokushisela i-AR1440, ngokunemba okuphezulu, isivinini esikhulu, umsebenzi we-spatter ophansi, amahora angu-24 oqhubekayo wokusebenza, ofanele ukushisela insimbi yensimbi, insimbi engagqwali, ishidi lama-galvanized, i-aluminium alloy nezinye izinto, ezisetshenziswa kabanzi ezingxenyeni ezihlukahlukene zezimoto, izinsimbi Ifenisha, imishini yokufaneleka, imishini yobunjiniyela kanye namanye amaphrojekthi wokushisela.

-

Yaskawa arc welding irobhothi AR2010

IYaskawa arc welding irobhothi AR2010, enebanga lengalo engu-2010 mm, ingathwala isisindo esingu-12KG, okwandisa isivinini irobhothi, inkululeko yokunyakaza kanye nekhwalithi yokushisela! Izindlela zokufaka eziyinhloko zaleli robhothi lokushisela i-arc yilezi: uhlobo lwaphansi, uhlobo olubheke phansi, uhlobo olubekwe odongeni, nohlobo oluthambekele, olungahlangabezana nezidingo zabasebenzisi ngezinga elikhulu kakhulu.

-

I-Yaskawa spot welding irobhothi MOTOMAN-SP165

II-Yaskawa spot welding irobhothi MOTOMAN-SP165iyirobhothi elinemisebenzi eminingi elihambisana nezibhamu zokushisela ezincane neziphakathi. Iwuhlobo lwe-multi-joint eyi-axis eqondile engu-6, enomthwalo omkhulu ongu-165Kg kanye nobubanzi obungu-2702mm. Ilungele amakhabethe okulawula e-YRC1000 futhi isetshenziselwe ukushisela indawo nokuthutha.

-

Yaskawa Spot Welding Robot SP210

IYaskawa Spot Welding RobotIndawo yokusebenzaSP210inomthwalo omkhulu we-210Kg kanye nebanga eliphakeme lika-2702mm. Ukusetshenziswa kwayo kuhlanganisa ukushisela indawo kanye nokubamba. Ilungele izimboni zamandla kagesi, zikagesi, zemishini, nezezimoto. Inkambu esetshenziswa kakhulu ishabhu yokuhlanganisa ezenzakalelayo yemizimba yezimoto.

www.sh-jsr.com

Imikhiqizo Eshisayo - Imephu yesayithiIrobhothi Lokushisela, I-Yaskawa Painting Robot, Irobhothi Lokupenda Okuzenzakalelayo, I-Palletizing Robot, Yaskawa Spot Welding Robot, I-Robot Palletizer,

Thola ishidi ledatha noma isilinganiso samahhala

Bhala umlayezo wakho lapha futhi usithumelele wona