Isikhundla

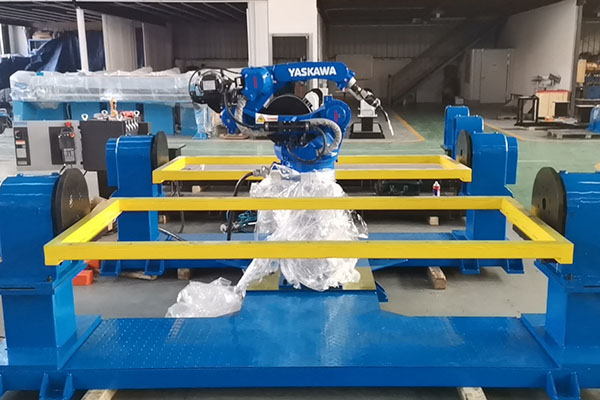

Iwelding irobhothi positioneriyingxenye ebalulekile yomugqa wokukhiqiza we-welding we-robot kanye nokuguquguquka kwe-welding plus unit.Imishini inesakhiwo esilula futhi ingajikeleza noma ihumushe isiqeshana sokusebenza esishiselwe endaweni engcono kakhulu yokushisela. Imvamisa, irobhothi elishiselayo lisebenzisa ama-positioners amabili, enye eyokushisela kanti enye ukulayisha nokukhipha ucezu lokusebenza.

electronics, nemishini, kanye namathuluzi omshini we-CNC, ama-turntable wokufafaza neminye imishini eyenziwe ngokwezifiso edinga ukushintsha indawo yomkhiqizo.

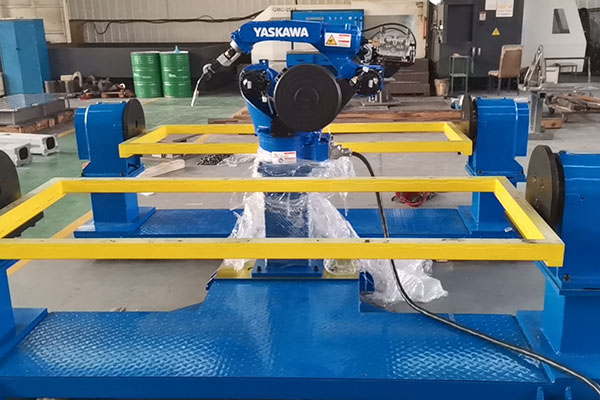

Ama-welding positionerszihlukaniswe zaba izinhlobo ezahlukene zokukhubazeka ezifanaama-positioners aseceleni, buyisela isikhundla, ukuphakamisa ama-positioners, ama-positioners aphindwe kabili, njll. Abasebenzisi bangazenza ngendlela oyifisayo ngokwezidingo zangempela zokukhiqiza. Kungenziwa ngokungafanele ifaniswe nemishini yokushisela ehlukene, futhi inhlanganisela ilungile. Yethula izixhumanisi ezaziwayo ukuze uhlole ngokucophelela ingxenye ngayinye ukuze uthuthukise ukunemba komkhiqizo nempilo yesevisi. Ukuhlanganiswa kwemishini nokunemba kokucubungula kuthuthukiswa kakhulu.

Ii-robot positionerisetshenziswa ngokubambisana ne-manipulator kanye nomshini wokushisela ukwakha isikhungo se-welding esizenzakalelayo, futhi singasetshenziselwa ukukhishwa kwe-workpiece ngesikhathi somsebenzi wezandla. Ii-welding positionerngokuvamile kwakhiwa umshini wokujula osebenzayo kanye nendlela yokujika. Ngokuphakamisa, ukujika kanye nokuzungezisa ithebula lokusebenza, ucezu lokusebenza olungaguquki kuthebula lokusebenza lungafinyelela i-engeli yomhlangano we-welding edingekayo. Ukuguqulwa kwethebula lokusebenza kusebenzisa ukulawulwa kwesivinini esingenasinyathelo se-inverter. , Ukunemba kokulawulwa kwesivinini esiphezulu. Ibhokisi lesilawuli kude lingakwazi ukubona ukusebenza okukude kwebhentshi lokusebenzela, futhi lingaxhunywa nomshini wokusebenza kanye nohlelo lokulawula umshini wokushisela ukuze kubonakale ukusebenza kokuxhumanisa.

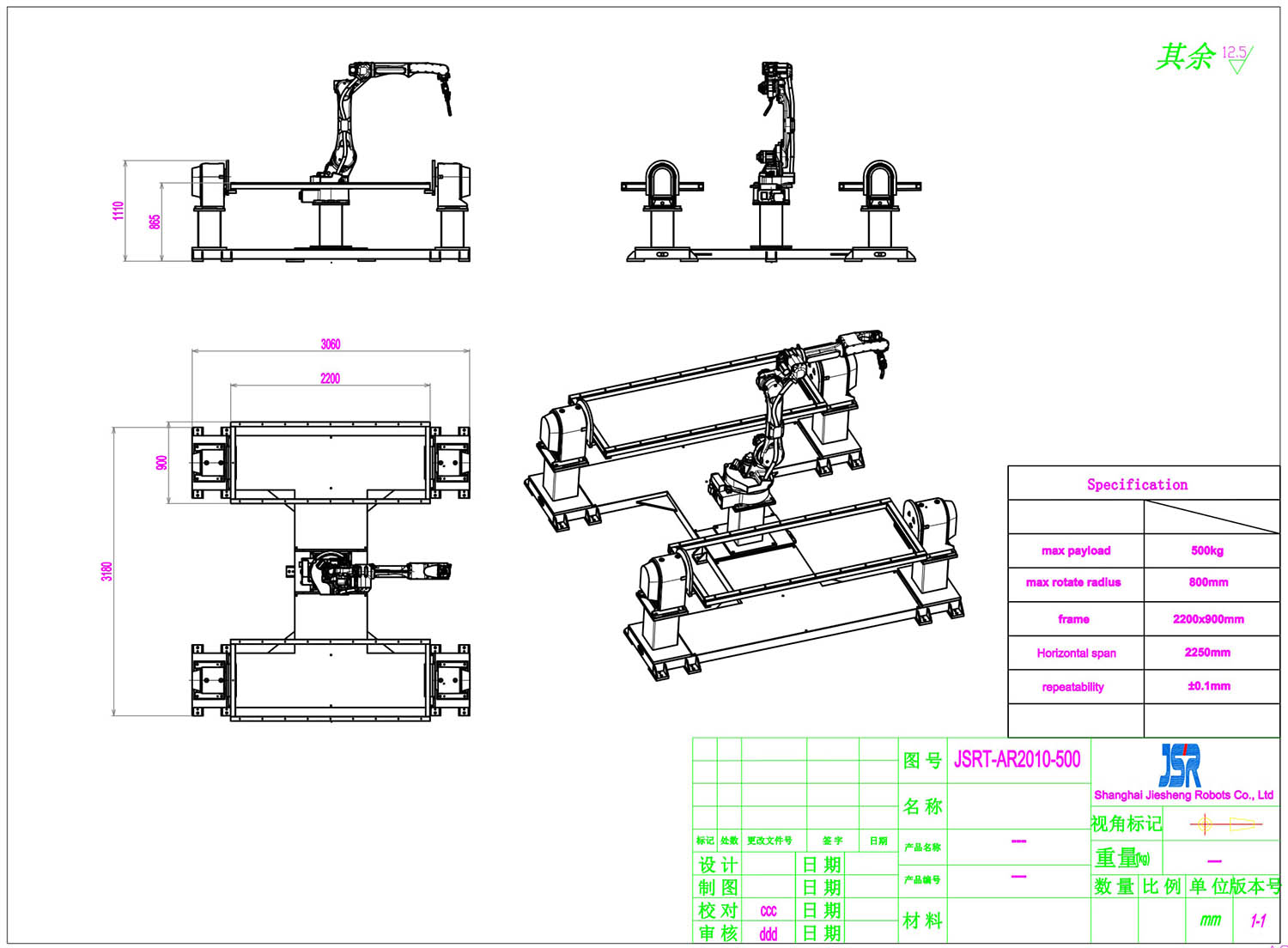

Ii-axis emithathu evundlile yokujika indawokweindawo yokusebenza yerobhothiisetshenziselwa ukuzungezisa i-fixture futhi iguqule ukuma kwemidlalo emibili. Ibanga lokuzungezisa: ±180°. Ngemuva kokuthi ukujikeleza kusendaweni, ibekwe ngokunembile nge-pneumatically ukuqinisekisa ukunemba kwe-welding. Phakathi nenqubo yokushisela, ukugudluzwa kwe-fixture kanye nokunyakaza okudidiyelwe kwerobhothi kungaphendula noma yisiphi isigaba se-weld endaweni efaneleke kakhulu yokushisela, futhi irobhothi lishayela ithoshi lokushisela ukuze lishisele ngendlela engcono kakhulu yokushisela. Tindawo ye-hree-eksisi+ Ukuxhumanisa kwemishini emibili kunciphisa ukuhlanekezela kokushisela futhi kwenza umsebenzi usebenze kahle.