Ukuthola i-Seam kanye nokulandela umthungo kuyimisebenzi emibili ehlukene esetshenziswa ekushiseleni okuzenzakalelayo. Yomibili imisebenzi ibalulekile ukuthuthukisa ukusebenza kahle kanye nekhwalithi yenqubo yokushisela, kodwa yenza izinto ezihlukene futhi incike kubuchwepheshe obuhlukahlukene.

Igama eligcwele lokuthola i-seam ukuthola indawo ye-weld. Umgomo uwukuthola izici zesici se-weld ngokusebenzisa ithuluzi lokubona i-laser weld, kanye nokwenza isinxephezelo sendawo nokulungiswa kuhlelo lwangempela ngokuchezuka phakathi kwendawo yephoyinti lesici esitholiwe nendawo yephoyinti lesici sokuqala esilondoloziwe. Isici siwukuthi kudingekile ukuqedela ukufundisa zonke izikhundla zokushisela ze-workpiece ukuqinisekisa ukuthi i-welding isetshenziswa ngokunembile ku-weld, okubaluleke kakhulu ukuqinisekisa amandla nobuqotho be-welding. Ukuthola ama-Seam kusiza ekunciphiseni iziphambeko ezinjengama-nick, ukugcwaliswa ngokweqile, kanye nokushiswa kwazo zonke izinhlobo zokushisela ezinezimo ezingafaneleki zomthungo kanye nokushisela okunezingxenye eziningi.

Ukulandelela i-seam kuqanjwe ngokushintshwa kwendawo yomthungo engalandelelwa ngesikhathi sangempela. Isimiso siwumsebenzi wokulungisa isimo samanje serobhothi ngokuthola izinguquko kumaphuzu wesici se-weld ngesikhathi sangempela. Isici ukuthi sidinga kuphela ukufundisa indawo yokuqala nesiphetho sesegimenti ye-weld ukuze kuqedelwe i-trajectory iyonke ye-weld. Inhloso yokulandelela i-seam ukuqinisekisa ukuthi ama-welds asetshenziswa ngokunembile kumthungo, ngisho noma i-seam ishintsha indawo noma ukuma. Lokhu kubaluleke kakhulu ukuze kuqinisekiswe amandla okushisela nokuvumelana, ikakhulukazi emisebenzini yokushisela lapho ama-welds amade anokuphazamiseka, ama-S-welds anamajika. Gwema ukuchezuka kwe-welding kanye nokwehluleka ukushisela ngenxa yezinguquko ekumisekeni kwe-weld seam, futhi ugweme inkathazo yokufaka inombolo enkulu yamaphuzu.

Ngokwezidingo zangempela zokukhiqiza, ukwengeza indawo yokushisela noma uhlelo lokulandelela i-weld kungathuthukisa ukusebenza kahle kwerobhothi lokushisela, kunciphise isikhathi sokusebenza nobunzima, futhi kuthuthukise ikhwalithi yokushisela yerobhothi.

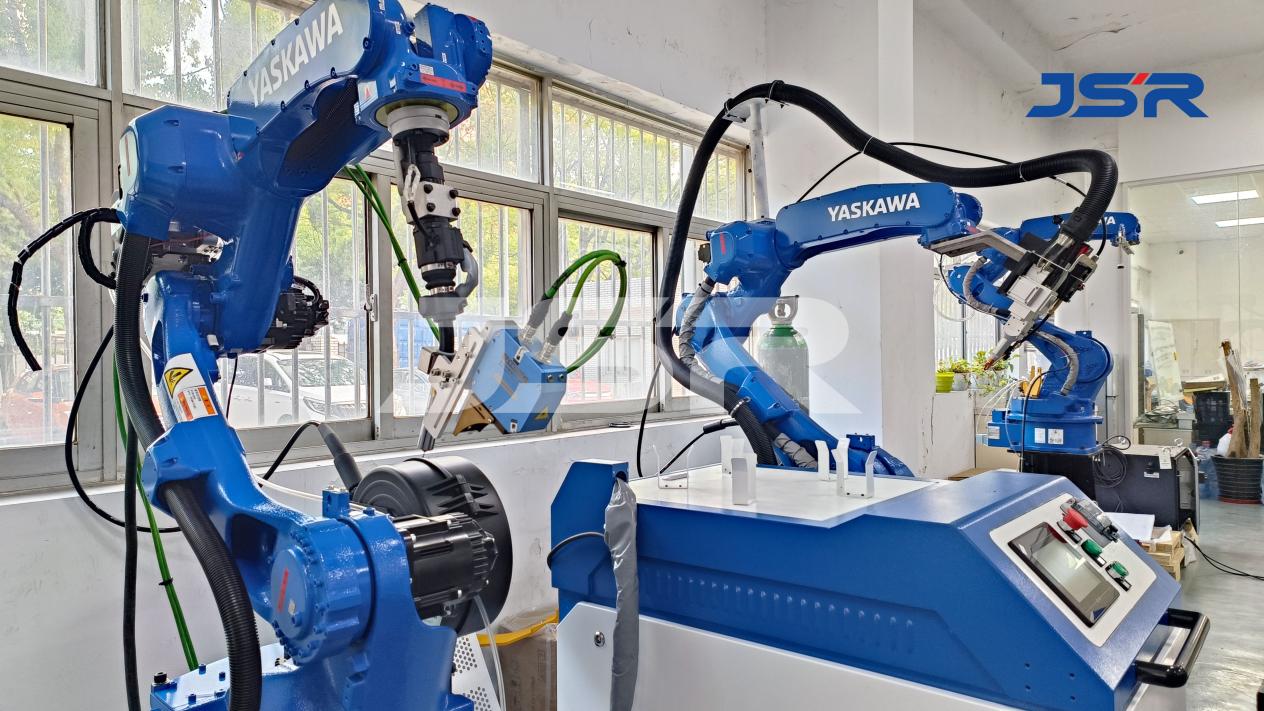

I-Jiesheng Robotics ibigxile ekuhlanganiseni indawo yokusebenza yamarobhothi, ukuhlanganiswa kwesistimu yokushisela nge-laser, kanye nokuhlanganiswa kwendawo yokusebenza yombono we-3D iminyaka engaphezu kweshumi. Sinolwazi olucebile lwephrojekthi. Uma unemibuzo, sicela ukhululeke ukuxhumana nathi.

Isikhathi sokuthumela: Apr-28-2023