Umehluko phakathi kwe-robot laser welding kanye ne-gas shielded welding

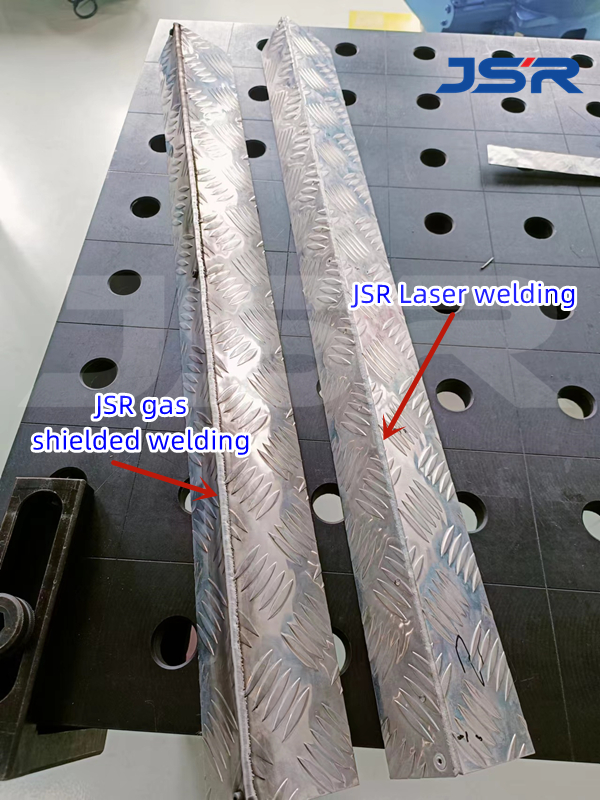

I-Robotic laser welding kanye ne-gas shielded welding yizindlela ezimbili ezivame kakhulu zobuchwepheshe bokushisela. Bonke banezinzuzo zabo kanye nezimo ezisebenzayo ekukhiqizeni kwezimboni. Lapho i-JSR icubungula izinduku ze-aluminium ezithunyelwa ngamakhasimende ase-Australia, isebenzisa lezi zindlela ezimbili zokuhlola ukushisela. Okulandelayo ukuqhathanisa imiphumela yokushisela yezinduku ze-aluminium, njengoba kuboniswe emfanekisweni:

Kuyini i-laser welding?

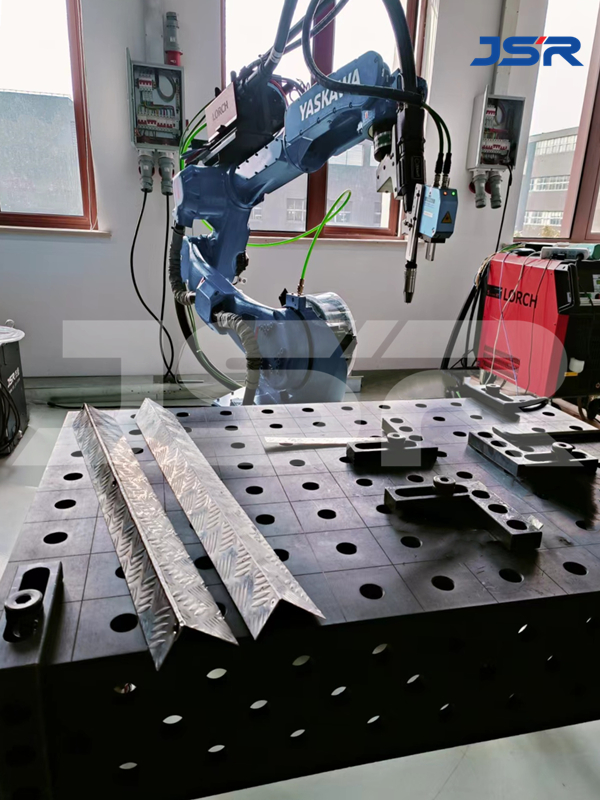

I-robotic laser welding: I-laser beam isetshenziselwa ukushisisa i-weld seam ibe yisimo esincibilikisiwe, futhi ukushisela okunembe kakhulu kutholakala ngokumiswa okunembile kwekhanda le-laser welding.

Iyini i-Gas shieded welding?

I-welding evikelekile yegesi: Isibhamu sokushisela sisetshenziselwa ukukhiqiza izinga lokushisa eliphezulu nge-arc kagesi, okwenza izinto zokushisela zincibilike ngenkathi indawo yokushisela ivikelwe emoyeni kanye nokunye ukungcola kwangaphandle ngegesi evikelayo (ngokuvamile igesi ye-inert).

https://youtube.com/shorts/Hfyqm0_tJ6c

I-Robot laser welding VS Igesi evikelekile yokushisela

1. Izinto ezisetshenziswayo:

• I-robot laser welding: Ifaneleka kakhulu izinto zokwakha ezacile, njengensimbi engagqwali, i-aluminium alloy, njll.

• I-Robot Gas-shielded Welding: Isebenza kabanzi kumashidi ensimbi ashubile, okuhlanganisa nensimbi.

2. Isivinini sokushisela:

• I-robotic laser welding: Ngokuvamile isivinini sokushisela siyashesha futhi sifanele izindawo zokukhiqiza eziphezulu. Isivinini sokushisela i-workpiece yamakhasimende e-JSR ngu-20mm/s.

• I-Gas-shielded Welding: Isivinini sokushisela ngokuvamile sihamba kancane kune-laser welding, kodwa kuseyisinqumo esibalulekile kwezinye iziqephu zokusebenza ezikhethekile nezigcawu ezinezidingo eziphezulu. Ijubane lokushisela i-workpiece esithombeni lingu-8.33mm/s.

3. Ukunemba nokulawula:

• I-robot laser welding: I-laser welding inezidingo eziphezulu emikhiqizweni. Uma kukhona izikhala emalungeni, kuzothinta ukushisela kwe-laser. Inezinga eliphezulu lokunemba nokulawula, futhi ifanele izikhathi ezidinga ikhwalithi ephezulu kakhulu yokushisela.

• Ukushisela okuvikelwe ngegesi: Inezinga eliphezulu lokubekezelela amaphutha emikhiqizweni futhi ingashiselwa ngisho noma kunezikhala ekuhlanganiseni komkhiqizo. Ukunemba kungaphansi kancane kunalokho kwe-laser welding, kodwa kusengasetshenziswa kwezinye izinhlelo zokusebenza ezinezidingo ezixekethile.

4. Umphumela wokushisela:

• I-laser welding yerobhothi: Ngenxa yokokufaka okuncane kokushisa, i-laser welding inomthelela omncane wokushisa endaweni yokusebenza, futhi umthungo wokushisela unokubukeka okuyisicaba nokushelela.

• I-Gas shielded welding: Ngenxa yokushisa okuphezulu kwe-welding, indawo yokushisela kulula ukuqubuka, ngakho ifaneleka izinto zokusebenza ezidinga ukupholisha.

Ukukhethwa kwe-robotic laser welding noma i-gas-shielded welding kuncike ezidingweni ezithile zokukhiqiza, okuhlanganisa ukucatshangelwa kwezinto, izidingo zekhwalithi yokushisela, ukusebenza kahle kokukhiqiza, ukucubungula okulandelwayo, njll. Kwezinye izimo, lezi ezimbili zingasetshenziswa ndawonye ukuze zinikeze ukudlala okugcwele ezinzuzweni zazo.

Isikhathi sokuthumela: Jan-23-2024